Our team of designers and glass experts is here to help you understand everything you need to know before deciding on ordering a custom glass table tops. When ordering glass table it is important to consider several points:

– First decide on the overall size and shape of the table. Our production facilities offers options to customize the shape of your table: round, oval or rectangular. You can incorporate glass furniture to become part of your interior by designing glass shapes matching the style and flow of the architecture.

– Next consideration would be the thickness. Generally you want the glass to be thick enough to maintain structural integrity. We recommend for smaller sized tables using at least 3/4″ tempered glass for table tops. It very common to use 1″ thick glass, with options to laminate two layers of 1/2″ together or use one solid glass of 1″ thickness. In special cases several layers of glass can be laminated together to create amazing thickness for glass countertops of up to 3″ thick. It is not recommended to making glass table that is less than 1/2” thick.

– Edges of the glass: it is important that you select the side finishing, that fits your need and style. Beveled or round edges are common requests for the sides of the glass table. Consider the angle of the bevel, as well as the depth from the edge to the bevel line. Contact Palace of Glass representative to help you decide what style of edging fit your designer glass table.

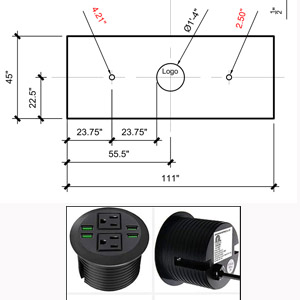

– In some cases holes can be made in the glass to insert some fittings or electrical outlets.

– Safety Glass: Palace of Glass glass table tops meet the safety standards and are either tempered or laminated.

– Customization of the Glass Tables can include unusual shapes and additional layers of lamination. Custom designs and logos can be engraved or etched on the surface of the glass. Colored patterns can be laser engraved to create textures and borders.

Please contact us about your next custom glass table top project and we help you customize glass per your vision and specifications.