The team of Palace of Glass designers is here to help you plan and visualize your custom glass project!

The Art of Precision: The Vital Role of Visual References in Custom Glass Projects

Working with glass is not merely about envisioning grand designs; it demands a high level of craftsmanship, meticulous planning, and precise execution. Central to this process is the creation of strong visual references, such as detailed sketches and 3D renders. These tools are indispensable in ensuring the success of custom glass projects. This article delves into the importance of these visual references and the necessity of coordination and preplanning with the installation team.

The Intricacies of Glass Craftsmanship

Glass, with its delicate nature and transformative potential, requires artisans who possess both skill and experience. Unlike other building materials, glass offers little room for error. A slight miscalculation can lead to misfits, structural weaknesses, or aesthetic flaws. Therefore, the margin for error is virtually nonexistent.

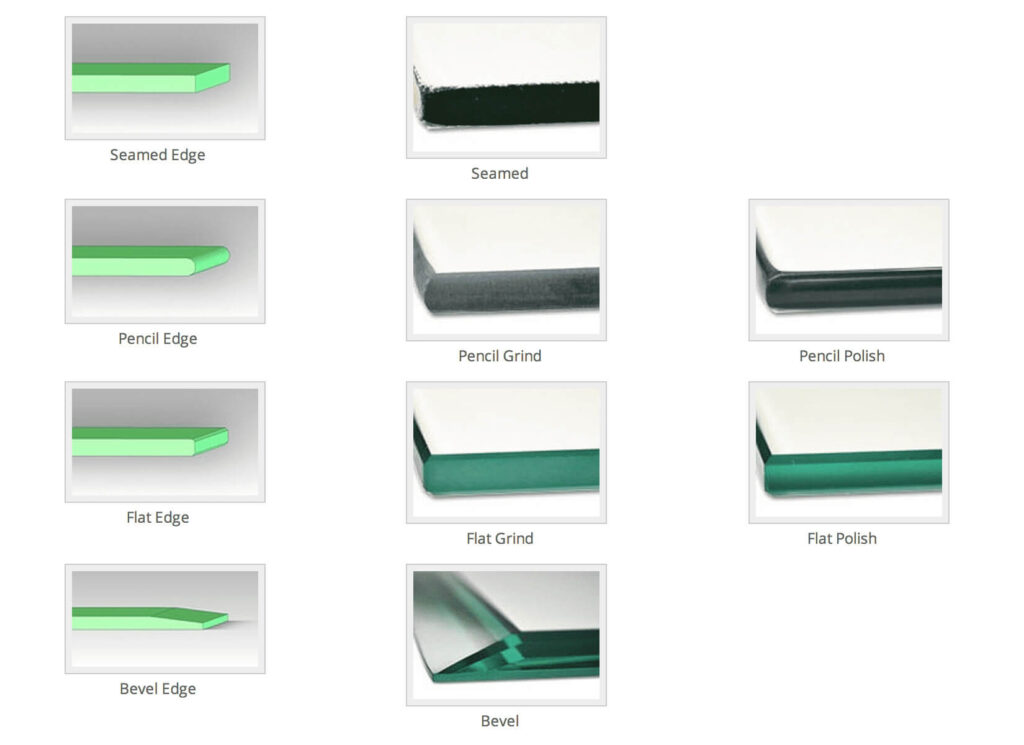

Crafting custom glass pieces involves understanding the material’s properties, such as its weight, tensile strength, and thermal expansion. Moreover, factors like edge treatments, coatings, and finishes add layers of complexity to the project. Given these intricacies, having a clear and precise visual representation of the intended design becomes paramount.

Why Visual References Matter

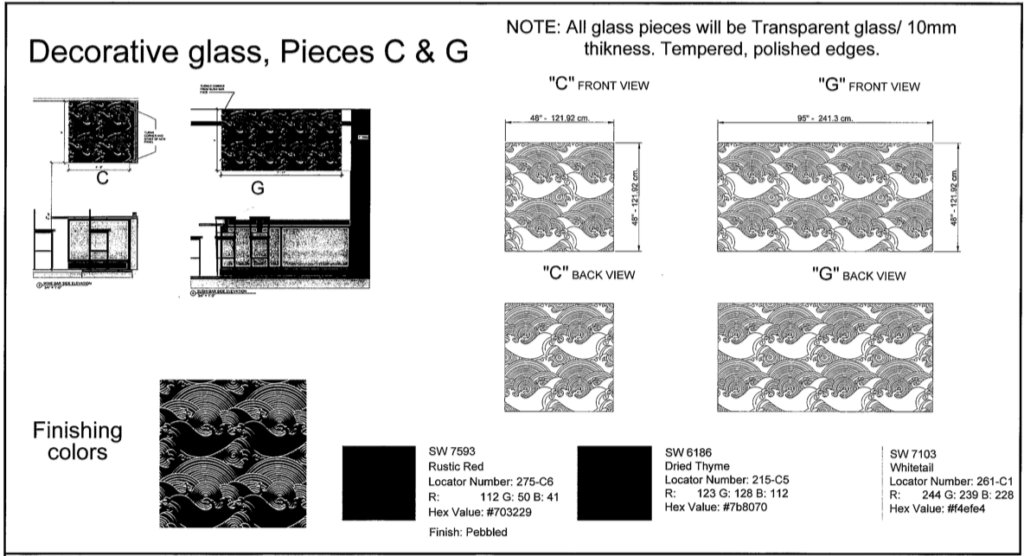

- Clarity of Vision At the heart of any design project lies a vision. For clients, this vision might be a blend of ideas inspired by various sources. For designers and craftsmen, translating this abstract vision into a tangible product is the challenge. Visual references bridge this gap. Detailed sketches and 3D renders provide a concrete representation of the final product, ensuring that all stakeholders share a unified understanding of the project’s goals.

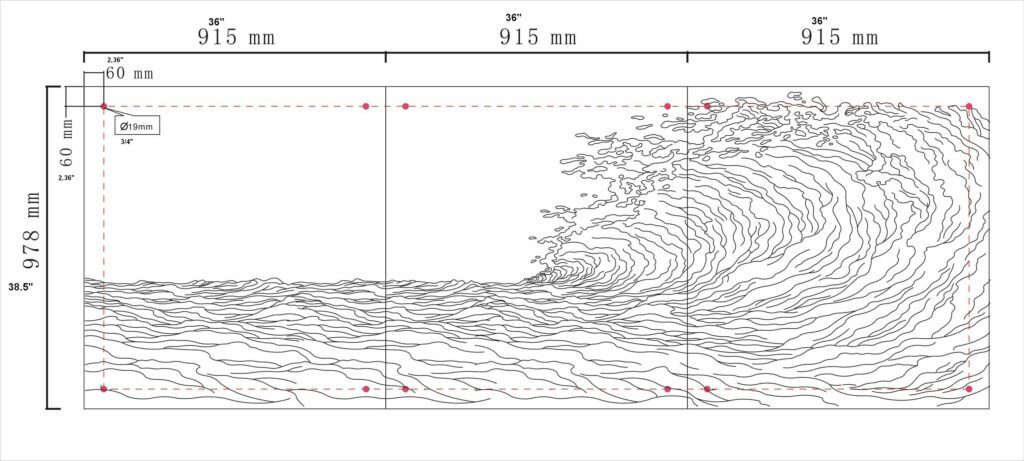

- Accuracy in Execution Precision is non-negotiable in custom glass projects. Detailed drawings outline exact dimensions, shapes, and specifications. They serve as blueprints guiding the craftsmen in cutting, molding, and assembling the glass pieces. Without such references, the risk of errors multiplies, leading to potential wastage of materials, increased costs, and prolonged timelines.

- Enhanced Communication Projects often involve multiple teams, including designers, craftsmen, engineers, and installation experts. Visual references act as a common language among these diverse groups. They facilitate discussions, highlight potential challenges, and enable collaborative problem-solving. For instance, an installer might identify potential issues in fitting a particular glass piece based on the 3D render, allowing for adjustments before fabrication.

- Client Assurance For clients, especially those investing in bespoke designs, seeing a visual representation instills confidence. It assures them that their vision is being accurately captured and provides an opportunity to request modifications before the commencement of production. This proactive approach reduces the likelihood of dissatisfaction upon project completion.

The Superiority of 3D Renders

While traditional sketches offer value, 3D renders have revolutionized the design process. Here’s why they are particularly beneficial:

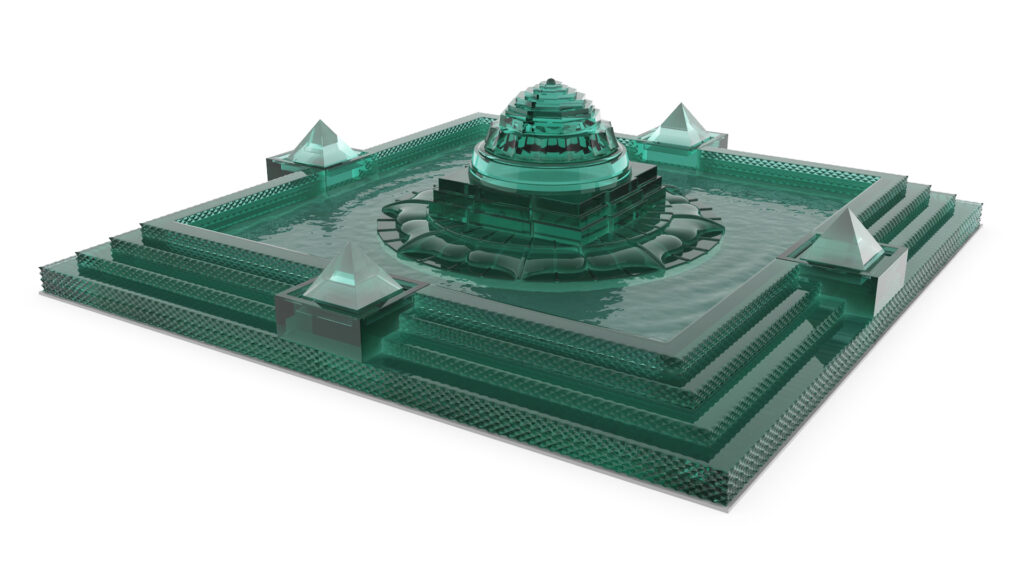

- Realistic Visualization 3D renders provide a lifelike depiction of the final product. They capture nuances like lighting effects, reflections, and shadows, offering a comprehensive view of how the glass piece will integrate into its environment.

- Exploration of Alternatives Designers can easily tweak aspects like color, texture, and finish in 3D models. This flexibility allows clients to explore various options and settle on choices that best align with their preferences.

- Detection of Design Flaws By simulating real-world conditions, 3D renders can reveal potential design flaws. For example, they can show how light interacts with the glass at different times of the day, highlighting issues like glare or unwanted reflections.

- Facilitating Technical Planning Detailed 3D models assist engineers and installation teams in understanding the spatial dynamics of the glass elements. They can assess factors like weight distribution, support structures, and integration with other materials.

Coordination with the Installation Team

The journey from design to installation is complex, especially with materials as demanding as glass. Early and continuous coordination with the installation team is crucial. Here’s why:

- Feasibility Assessment Installers bring practical insights into the table. They can evaluate whether the design is feasible given the site conditions, available technology, and logistical constraints.

- Preemptive Problem-Solving By involving the installation team during the design phase, potential challenges can be identified and addressed proactively. This collaborative approach minimizes on-site surprises and delays.

- Ensuring Structural Integrity Installers ensure that the glass elements are integrated safely and securely. Their input is vital in determining support mechanisms, anchoring points, and safety measures.

- Streamlining the Installation Process Detailed visual references, when shared with the installation team, allow for meticulous planning. They can organize resources, schedule tasks efficiently, and anticipate requirements, ensuring a smooth installation phase.

Preplanning: The Pillar of Success

Preplanning is the bedrock upon which successful custom glass projects are built. It encompasses:

- Accurate Measurements Precise dimensions are vital. Even minor discrepancies can lead to misalignments, compromising the project’s integrity.

- Material Selection Deciding on the type of glass, finishes, and treatments ahead of time ensures availability and prevents delays.

- Budgeting Detailed plans and visual references aid in accurate budgeting, preventing unforeseen expenses.

- Timeline Management With clear plans, stakeholders can establish realistic timelines, coordinating fabrication, delivery, and installation phases seamlessly.

Conclusion

Custom glass projects are a harmonious blend of art and engineering. Achieving the delicate balance between aesthetic appeal and structural integrity demands meticulous planning, skilled craftsmanship, and effective communication. Strong visual references, be it detailed sketches or advanced 3D renders, are the linchpins of this process. They not only crystallize the design vision but also serve as invaluable tools for coordination, execution, and quality assurance.

Investing time and resources in creating these visual guides pays dividends in the form of streamlined workflows, reduced errors, and enhanced client satisfaction. Moreover, proactive coordination with installation teams and thorough preplanning ensure that the final product not only meets but exceeds expectations.

In the world of custom glass design, where transparency meets intricacy, let the design team at the Palace of Glass bring clarity of vision and precision of execution. Embrace the power of visual references, and watch your glass masterpieces come to life with unparalleled elegance and perfection.